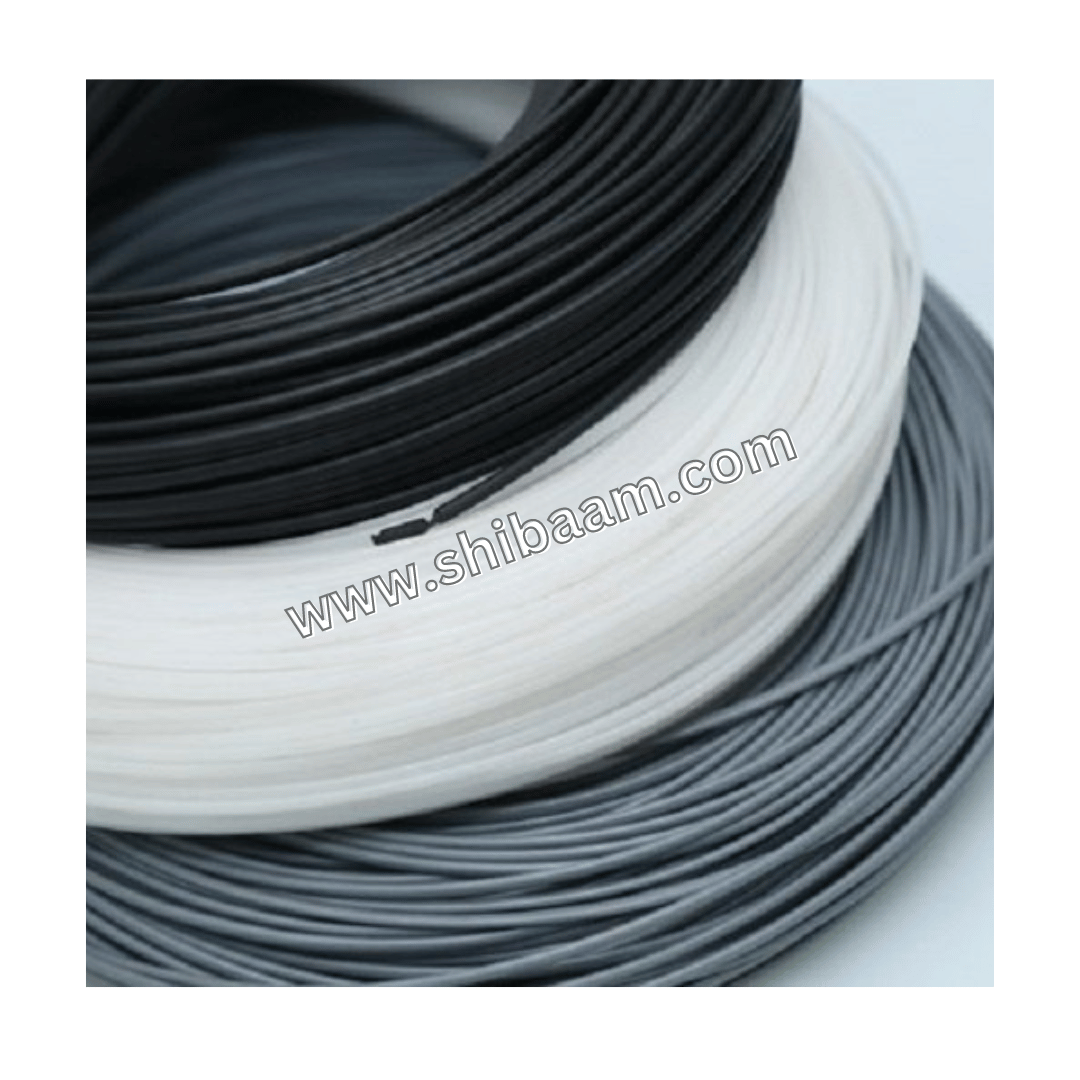

PP Welding Rods

Polypropylene (PP) welding rods are essential materials used in the process of welding polypropylene. Polypropylene is a thermoplastic polymer known for its versatility, chemical resistance, and low-density properties. PP welding is commonly used in various industries for fabricating tanks, pipes, and other equipment where a strong and durable joint is required.PP welding rods are specifically made from polypropylene, ensuring compatibility with the base material being welded.