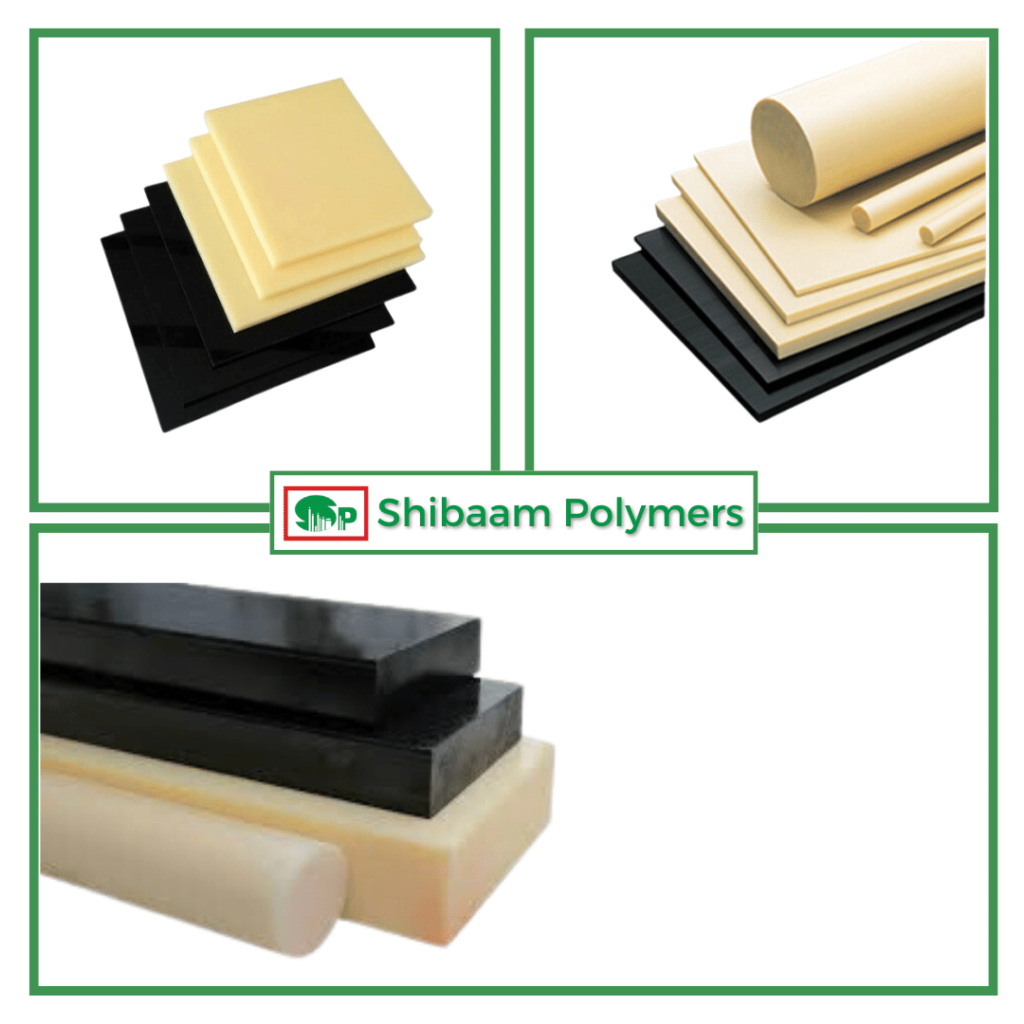

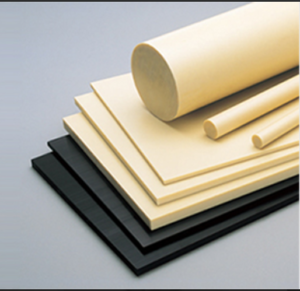

ABS

Shibaam Polymers presents a comprehensive range of ABS (Acrylonitrile Butadiene Styrene) products designed to exceed industry expectations. ABS is celebrated for its exceptional blend of toughness, versatility, and durability, making it an ideal choice across a multitude of applications and sectors. At Shibaam Polymers, we take pride in providing high-performance ABS products that meet your specific needs and exceed industry standards. Whether you require robust durability, efficient fabrication, or resilience in challenging conditions, our ABS products stand as a testament to our commitment to engineering excellence.