High Abrasion Resistance: PU screens have excellent wear resistance, making them ideal for screening coarse and abrasive materials like sand, gravel, ores, and other aggregates

Vibration Resistance: Polyurethane screens are designed to perform well under vibrating conditions, providing optimal separation in vibrating screens used in mining and aggregate applications

Flexibility and Durability: PU screens are flexible and can absorb impacts without cracking or breaking, ensuring longer life in tough screening conditions

Chemical Resistance: Resistant to a wide range of chemicals, including oils, solvents, and many industrial substances, PU screens are suited for environments with harsh chemicals

High Load-Bearing Capacity: PU screens can handle heavy materials without losing their shape or effectiveness

Water Resistance: Polyurethane does not absorb water, making it ideal for wet conditions and outdoor applications

Noise Reduction: The elasticity of polyurethane reduces noise during the screening process, making it suitable for environments where noise is a concern

Customizable Sizes and Shapes: PU screens can be made in a variety of shapes, sizes, and hole patterns to fit specific machines and processes

UV Resistance: Some PU screens are UV-stabilized to provide resistance to sunlight degradation, making them suitable for outdoor use

Mining and Quarrying: Used in vibrating screens for the separation of rocks, ores, sand, and other materials. PU screens are ideal for handling abrasive materials like gravel and coal

Aggregate Production: Used for classifying and separating different sizes of crushed stone, sand, and gravel

Recycling: Employed in the sorting of recyclable materials such as plastic, paper, and metal in waste management systems

Construction: Used for screening construction materials, including soil, sand, and aggregate

Chemical Industry: Employed in the separation and filtration of chemicals, slurry, and other liquid-solid mixtures

Food Processing: Used for sorting and separating ingredients, ensuring quality control in food production and processing lines

Environmental Protection: Used in wastewater treatment plants to screen out large particles before further treatment

Pulp and Paper: Employed in the screening of fibers and other materials in the pulp and paper manufacturing process

Durability: Longer service life compared to rubber and metal screens, especially in abrasive environments

Low Maintenance: Reduced need for frequent replacement or repairs due to the resilience and wear resistance of PU

High Efficiency: PU screens help increase the efficiency of material separation by providing better openings for materials to pass through

Cost-Effective: While PU screens may have a higher initial cost, their durability and longevity make them cost-effective over time

Custom Fit: PU screens can be manufactured to suit specific applications, ensuring they fit into existing machinery and processes

Reduced Downtime: Longer-lasting and more resilient, reducing the frequency of downtime due to screen failures

Noise Reduction: The material’s ability to absorb sound makes it suitable for environments where noise levels must be controlled

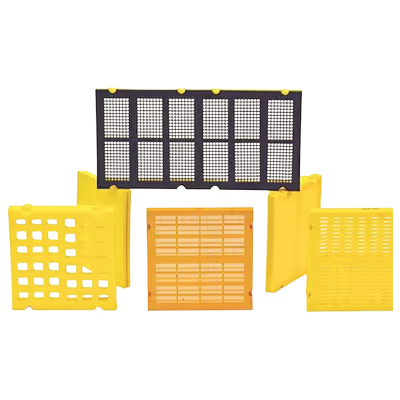

Mesh Size and Hole Patterns: PU screens can be made with varying mesh sizes, hole shapes, and patterns (e.g., round, square, slotted) to suit specific separation requirements

Hardness Levels: PU screens can be manufactured in different hardness grades to match the rigidity required for the application

Shape and Size: Custom sizes and shapes are available to fit specific equipment, such as vibrating or static screens

UV Protection: UV-stabilized PU screens can be made for outdoor or sun-exposed applications

Chemical Resistance: PU screens can be formulated to resist specific chemicals based on the needs of the application

Anti-Clogging Design: Certain PU screens can be designed to prevent clogging in applications that involve fine or sticky materials

Regular Inspection: Inspect PU screens periodically for signs of wear or damage, particularly in high-abrasion environments

Cleaning: PU screens should be cleaned regularly to remove build-up of materials, especially in wet or slurry applications

Repairs: Minor damages can be repaired with PU-based adhesives, or the affected section can be replaced

Storage: Store PU screens in a dry, temperature-controlled environment to avoid degradation from exposure to extreme heat or UV light when not in use